- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

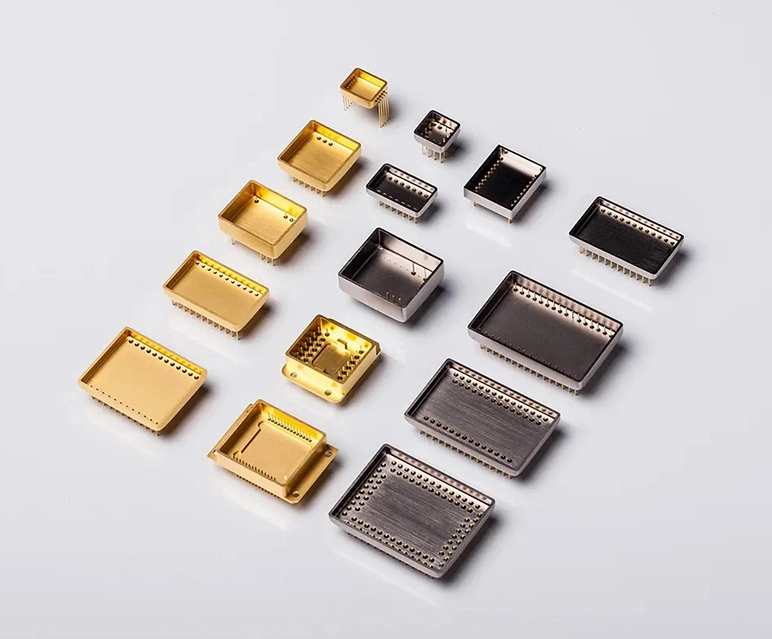

Filters and precision components are increasingly deployed in environments where moisture, temperature extremes, pressure fluctuations, vibration, and chemical exposure are unavoidable. In such conditions, the reliability of the packaging becomes just as important as the design of the filter or comp

Electronics and sensitive components are no longer confined to clean, climate-controlled environments. Today, they must operate reliably in extreme heat, freezing cold, high humidity, corrosive atmospheres, high pressure, and intense mechanical stress. Hermetic packaging has emerged as a proven solu

From consumer gadgets to aerospace systems, hermetic packaging material must meet strict requirements for protection, performance, and cost.Ceramic and plastic packages are two widely debated options, each with strengths and trade-offs in protecting sensitive electronics from thermal stress, moistur

When it comes to selecting the right transistor outline (TO) package for your electronic components, the decision can be crucial to the efficiency and reliability of your system. TO packages are a standard form factor used for encapsulating electronic components such as transistors, diodes, and othe